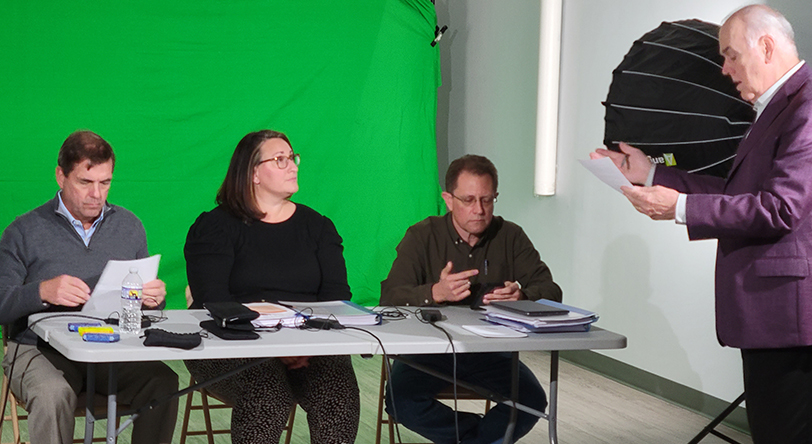

Three judges for the 68th Annual Flexible Packaging Achievement Awards Competition for 2024 sit behind a plain white table with a large “green screen” behind them. As they settle in to discuss the contest and award winners, Bryan McLamara gives them direction. McLamara is the production manager, cinematographer, and editor for Visual Impact Productions, LLC (VIP).

The judges are doing dual duty today: selecting winning entries and starring in a video that will be shown during the Flexible Packaging Association’s (FPA’s) Welcome & Achievement Awards Dinner at the Annual Meeting being held March 20–22, when industry leaders will celebrate the innovations and visual appeal demonstrated in the packages.

The judges each have a camera focused on them so they should look directly into the lens in front of them, McLamara tells them, as he checks the sound and guides his two camera operators to double-check the cameras. The judges should act naturally and not worry about making mistakes, which can be edited out later, he explains. For now, they should try to be upbeat and think of American Idol or The X Factor, popular television contests that rely on judging as part of their programming.

“It is basically like that,” McLamara says. “Alright, this is great. This is exciting. Whenever you are ready.”

And with that final instruction, the filming begins.

Judging the Contest

The temporary studio is set up in empty office space just down the hall from the FPA headquarters off Admiral Cochrane Drive in Annapolis, Maryland. This is the second day of judging for Chelsey Quick, vice president of client success at Industry Intelligence Inc.; Danny Beard, a consultant who is principal at Packaging Specialists based in Georgetown, South Carolina; and Bruce Welt, Ph.D., a professor in the packaging engineering program at the University of Florida (UF).

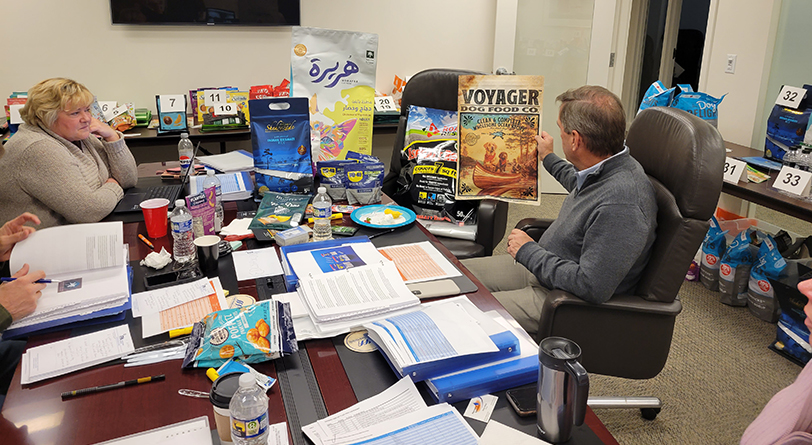

On the first full day of judging held the day before, the group examined more than 100 packages sent into the contest by dozens of companies from around the world that create flexible packages.

On this second day, the judges focus on picking the winners, including those for the gold and silver awards in six categories: expanding the use of flexible packaging, technical innovation, sustainability, printing, shelf impact, and packaging excellence. These winners will be notified before the FPA 2024 Annual Meeting so companies can plan to attend. But the announcement of the top prize—the Highest Achievement Award—is withheld until the awards dinner at the Loews Ventana Canyon Resort in Tucson, Arizona.

As they go through the entries, the judges review the summaries provided in advance by the companies. Details include technical specifications and descriptions of what makes the entries stand out. The judges aren’t told what companies produced the packages, an effort at anonymity intended to ensure their observations are as objective as possible.

‘Suitable for Framing’

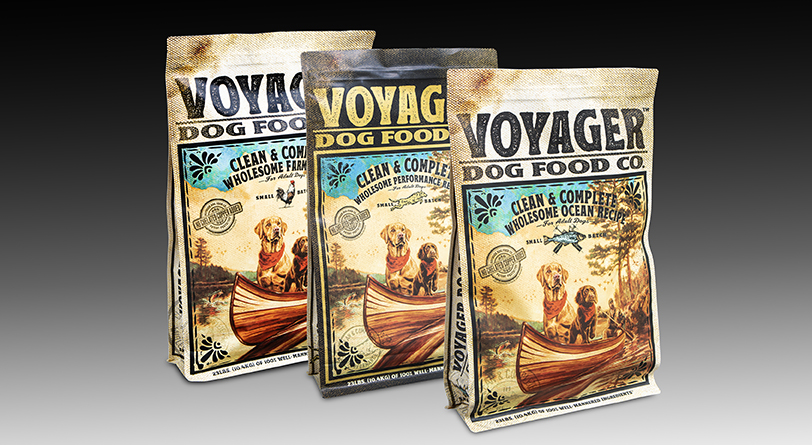

When it comes to printing and shelf impact, however, subjective senses take over—a testament to how some entries grab the judges’ attention immediately. One such entry is a large flexible packaging bag of dog food.

“This package was just gorgeous,” Quick says. “It just caught all of our eyes as soon as we walked into the judging room. We were excited to learn more about it. It represents what is a high-end product for pets.”

Beard and Welt agree.

“This is suitable for framing,” Welt says about the package. “This is a beautiful image on the front, and it is printed on all sides.”

The package, Beard adds, makes the judges proud to be part of the flexible packaging industry.

“It is durable, rugged, and it’s a great representation of what flexible packaging can be,” Beard says.

Several other packages receive the accolade of “suitable for framing” because of the artistic merits of the designs.

Innovations

Beyond beauty and shelf appeal, the judges are impressed with some of the innovations, especially when a package expands the use of flexible packaging. One rice bag stood out for Quick.

“The bag with a handle was a standout favorite for me as soon as I saw it,” she says. “I loved it. The function on the handle was unique. And the bag itself was beautiful and so that was by far a highlight for me.”

Another example was a pouch that holds a system to filter water, so just about any water can be turned into drinking water, Beard says. It would be suitable for hikers, bikers, campers, or anyone who would need access to drinking water in the wild, he and the other judges point out.

“This is an innovative product that shows an extension of flexible packaging,” Welt says.

Welt also liked an innovation with a frozen yogurt package, which offered two ways to consume the product. A problem with a traditional package is frozen yogurt often melts after being left in a lunchbox or when traveling.

“If you were to open it, it would spill and create a mess,” Welt says. “But with this package, you have both features—you could drink out of it, or you could eat it frozen—so it was an interesting innovation.”

The judges are impressed by a hook-and-loop closure for a pouch of pet food, noting how the closure will keep the food fresh longer. One large package is for an asphalt repair kit. Essentially, the judges quip, the package is a big bag of rocks. However, they note the innovation replaces large plastic tubs.

“The beauty of flexible packaging is that you can design the package to meet the specific needs of the product,” Beard says.

In addition to that, Welt points out, by moving from a large plastic pail to a flexible package, there is a sustainability story there, too.

Quick mentions that the average person might not notice that moving to a flexible package for the asphalt kit will reduce shipping costs, lower greenhouse gas emissions, and cut back the materials needed for packaging. “All of that has an impact,” she says.

Key Takeaways

This is Welt’s first experience with judging. Beard and Quick have been involved with similar contests in the past through other organizations, and they all point out some key takeaways from their two days of judging.

At Industry Intelligence, which curates and aggregates market news and information specific to a client’s needs, analysts work with various FPA members.

“Understanding what is important from an innovation standpoint is always a great talking point,” Quick says. “I can understand the trends that are happening in a better way. When we look at the innovation, the sustainability, and the different markets getting a lot of attention like pet food, I can take that back to our editorial team. It gives them insights into what companies are working on, what is happening in the markets, and what consumers want.”

Since COVID-19, consumers have been investing more in their pets, she points out.

“That plays into everything we are seeing here—the beautiful packaging and the more high-end luxury representations in the pet category,” Quick says.

She also takes notice of how companies are handling sustainability messaging on their packages, knowing that consumer education will be increasingly important.

“Having consumers pick up a package and understand what to do with it at the end of life has become critical,” Quick says, adding that consumers have good intentions but often don’t know what to do with their packages. “Even the best intentions get confused when you are standing in front of the bin thinking, ‘Can I recycle this?’ Having clear instructions on the package makes a big difference.”

The judges also recognize how stakeholders along the supply chain—from converters to chemical companies to consumer packaged goods companies—have been creating partnerships to solve problems while meeting the needs of consumers.

One package contains 20 refills for WD-40, which they point out is the equivalent of 20 cans of lubricant.

“Look at the shelf space and the materials not being wasted,” Quick says. “It’s a huge sustainability play on that.”

Speaking generally about sustainability efforts, Beard mentions that a sustainability story can be told about virtually any package. The trick is to tell a story that shows true innovations or to highlight other elements that make a package stand out.

He says he noticed improvements with post-consumer recycled (PCR) resin. The percentage of PCR content in packaging continues to increase, and companies have been learning when to use that content in packaging where the imperfections in PCR packaging are not as important to the consumer, Beard adds.

“But there is no one magic material,” he says. “I think the message that the industry is giving to clients is that there is not one solution for sustainability. The key takeaway is that there are several different sustainability solutions.”

Innovations in chemical and advanced recycling were evident in some entries, as well, the judges point out.

Welt and Beard commend entries that use flexible packaging created from pyrolysis, where the chemical recycling process creates PCR resin from carbon.

Rather than talk about such systems in terms of chemical or advanced recycling, Welt says, he prefers to talk about a system’s robustness. For example, mechanical systems create recycling streams through the sorting process, with desired products separated out and recycled based on the market demand for a given product. That would be low on a robustness scale.

“Pyrolysis on that spectrum provides more robustness. It can generally handle all the polyolefins—so you are talking all the polyethylene—and we don’t worry about color and filth and things like that,” he says. “Generally, if it’s polyethylene and polypropylene, it can go in. And then we can make new plastics from the material that comes out of that.”

At UF, Welt has been perfecting the use of synthesis gas to create methanol that can then be turned into plastics, which he says is “completely robust” and still being developed commercially, primarily in China and in other industries. It might be a few years before judges start to see packaging made at a commercial scale using Eco-Methanol™, but it is coming “because it has to,” he adds.

For now, the judges say, the industry must keep educating policymakers and consumers about the benefits of flexible packaging. The contest is one way to show what flexible packaging offers.

“The flexible packaging industry has an amazing story to tell,” Beard says. There is only so much light-weighting that can be done with other materials. “With flexible packaging, we are not even there yet—we can go lighter on a lot of packages. Plus, it has all the functionalities. And the functionality is really cool and interesting.”

Editor’s note: In the caption for the image at the top of this article, Tom Madden, executive producer and president of Visual Impact Productions, LLC, (VIP) gives guidance to the judges of the annual FPA contest after they moved to a temporary studio down the hall from FPA’s office. Seated from left are Danny Beard, principal of Packaging Specialists; Chelsey Quick, vice president of client success at Industry Intelligence Inc.; and Bruce Welt, Ph.D., a professor in the packaging engineering program at the University of Florida. The green screen behind the judges allows VIP to flash various images throughout the video.

Thomas A. Barstow is senior editor of FlexPack VOICE®.