A Texas company recently announced that it will invest $1.1 billion toward building an advanced manufacturing facility in Pennsylvania to convert post-consumer plastic materials into feedstock for new products—an effort the company says will contribute to the circular economy.

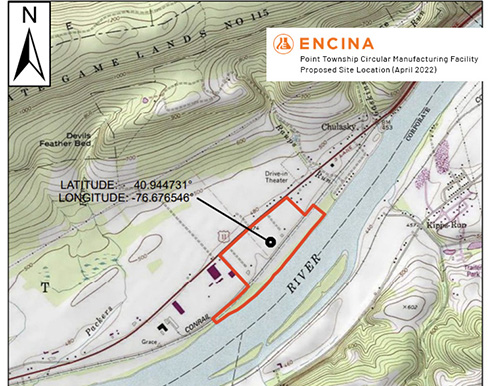

Houston-based Encina Development Group intends to build the plant in Northumberland County in north central Pennsylvania. The facility will be on more than 100 acres along the Susquehanna River. After completion, the project will create 300 full-time jobs, the company says in a news release.

Known as The Point Township Circular Manufacturing Facility, it will be the first facility in the region to use advanced technologies to convert post-consumer materials into feedstock, the company says. It will process 450,000 tons of post-consumer materials, diverting much of that from landfills and incinerators. That will reduce the need to produce new plastic from oil and gas resources, adding to the circular economy, the company also says.

“Increasingly, customers are demanding sustainable practices across the product supply chain and life cycle,” says David Roesser, Encina CEO. “The feedstocks we manufacture reduce waste, offset the need to produce virgin materials, and help manufacturers achieve carbon-neutral goals as we transition to a circular economy.”

Encina has a facility in Texas and plans operations later this year in Asia, with targets to operate in Mexico and Brazil in 2023, according to its website, encina.com. It also is working to establish operations in Europe.

The company says it chose Pennsylvania for its next project because of the state’s access to markets and a skilled workforce. “We’re committed to being an engaged partner as we build long-lasting and mutually beneficial relationships with the local community and businesses,” Roesser says.

In a statement, Pennsylvania Gov. Tom Wolf says the project will create good jobs. The Pennsylvania Manufacturers’ Association did an analysis of the project and estimates that the combined total of the construction and operations over five years will result in 1,956 jobs. “Encina’s technology will help address the challenges of post-use products and reduce the need for virgin materials to advance a circular, sustainable economy,” the association says in an overview of its analysis.

The company says it is in the permitting phase and is conducting feasibility studies on the site. Construction is expected to begin this fall and take 24 months, with the plant fully operational by the fall of 2024. Encina, which was founded in 2016, says that its process is different from mechanical recycling, where plastics can degrade over time while being recycled for use in other products. “Our advanced system can accept a wider range of plastic inputs—including unsorted and difficult-to-recycle plastics—and is, therefore, more effective in reducing waste streams that end up in the wrong places,” the company says on its website, adding that it uses established technologies in its process. “In addition, our process does not cause the same kind of degradation in quality. It can be used repeatedly to produce virgin chemicals, which can then be used by our customers to make new products that meet high quality and color standards.”

Thomas A. Barstow is senior editor of FlexPack VOICE®.