Nationwide, industries have been struggling to find well-trained workers, and the packaging and flexible packaging industries have not been immune. For the rest of this year, FlexPack VOICE® will profile some of the colleges, universities, and schools that have developed programs to train our future workforce. In this edition, we talk to Shyam S. Sablani, Ph.D., a professor in Washington State University’s food packaging program in Pullman, Washington.

FLEXPACK VOICE®: Tell us about the packaging program at your school.

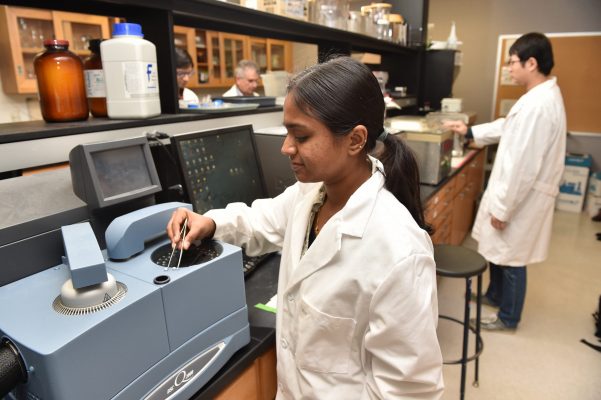

Shyam S. Sablani: The packaging program at Washington State University is an integral part of the food engineering graduate program in the department of biological systems engineering. Students in the program are trained in conventional and novel food processing and packaging technologies and receive Master of Science or doctoral degrees from the college of engineering and architecture. In the packaging area, students acquire skills in the design and development of commercially viable and sustainable packaging for food. Students study package fabrication methods, physical properties of packaging materials, packaging waste management, active and intelli-gent packaging, and shelf life of packaged foods.

FPV: What are the key skills that employers are looking for when hiring from your program?

SS: Food manufacturing companies hire our graduates. The companies appreciate that our students receive systematic training in conventional and advanced food processing technologies, in addition to food packaging. Through research, students gain hands-on experiences in packaging material and component testing using laboratory equipment. They are experienced in designing experiments to study the influence of manufacturing processes on package performance and the shelf-life determination of packaged foods. In addition, employers want our graduates that acquired soft skills, including communication, interpersonal, presentation, oral, and written. And they want workers who can easily adapt to change and are critical thinkers, as well as highly motivated.

FPV: What emphasis do you put on flexible packaging?

SS: We primarily use flexible packaging materials in our research related to advanced food preservation technologies. We emphasize using novel technologies and methods to improve gas and vapor permeabilities of multi-layer packaging films, the influence of food processing technologies on barrier properties of films, food and packaging interaction, and the influence of barrier properties on the shelf life of packaged foods.

FPV: What do you see as the future challenges in the packaging industry?

SS: Packages are necessary for food safety and shelf-life extension. Yet, consumers may only see the negative aspect of packages and consider packaging as increasing the burden on the environment. The packaging industry needs to educate consumers about the role of packaging in improving the safety and shelf life of food. In collaboration with research institutions and universities, the packaging industry needs to develop more sustainable packaging solutions, including reusable packaging and recycling of packaging materials. The industry needs to work with state and city governments and private entities to develop infrastructures for cost-effective collection of packages after use to reuse and recycle.

FPV: Anything you would like to add?

SS: Consumer contribution is central to the development of sustainable packaging solutions. There is a need to educate consumers about their role in reducing and managing packaging waste.