Advancements Make Compostable Packaging Possible

Compostable No Longer Just a Buzzword

The demand for compostable packaging to replace traditional plastic food and beverage packaging is growing steadily, and that trend is predicted to continue for years to come. It’s no surprise that consumers are excited about the idea of products that will essentially disappear into the earth instead of piling up in landfills or our environment.

However, taking this concept to completion has been challenging for packaging manufacturers because creating fully functional, compostable packaging relies on a lot of factors, including testing to make sure the product is compostable in the right conditions, as well as having access to compostable materials that achieve the desired performance and regulatory requirements for the application. It has been a long road, but the future looks hopeful thanks to new testing, products, and technologies.

The concept of compostable packaging is not new. Packaging professionals have been working to create compostable packages for decades. However, whether products that claimed compostability prior to the early 1990s actually degraded is up for debate. Thirty years ago, there was no formal definition—nor enforced testing requirements—for compostable products, which meant that manufacturers could promote their products as compostable—or make any other number of environmental claims—without any verification. In 1992, the Federal Trade Commission (FTC) started to regulate these claims by issuing and enforcing the “Green Guides,” which provide clear definitions of environmental terms, including the term “compostable,” as well as the appropriate situations where marketers could use each term. The guidelines in place for compostable products state that marketers should “possess competent and reliable scientific evidence showing that all the materials in the product or package will break down into, or otherwise become a part of, usable compost (e.g., soil conditioning material, mulch) in a safe and timely manner in an appropriate composting program or facility, or a home compost pile or device.”

Gathering Evidence

But where exactly were packaging manufacturers supposed to obtain that scientific evidence? In 1990, the American Society for Testing and Materials (ASTM, which is now known as ASTM International) organized Subcommittee D20.96 on Environmentally Degradable Plastics and Biobased Products. This new committee was tasked with developing science-based standard test methods and specifications regarding degradability and environmental claims being made. Since the early 1990s, the committee has developed a variety of standards with regard to biodegradation and compostability, but it wasn’t until 1999 that they developed the ASTM D6400—the specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities. It still is one of the most widely recognized standards for compostable testing to date.

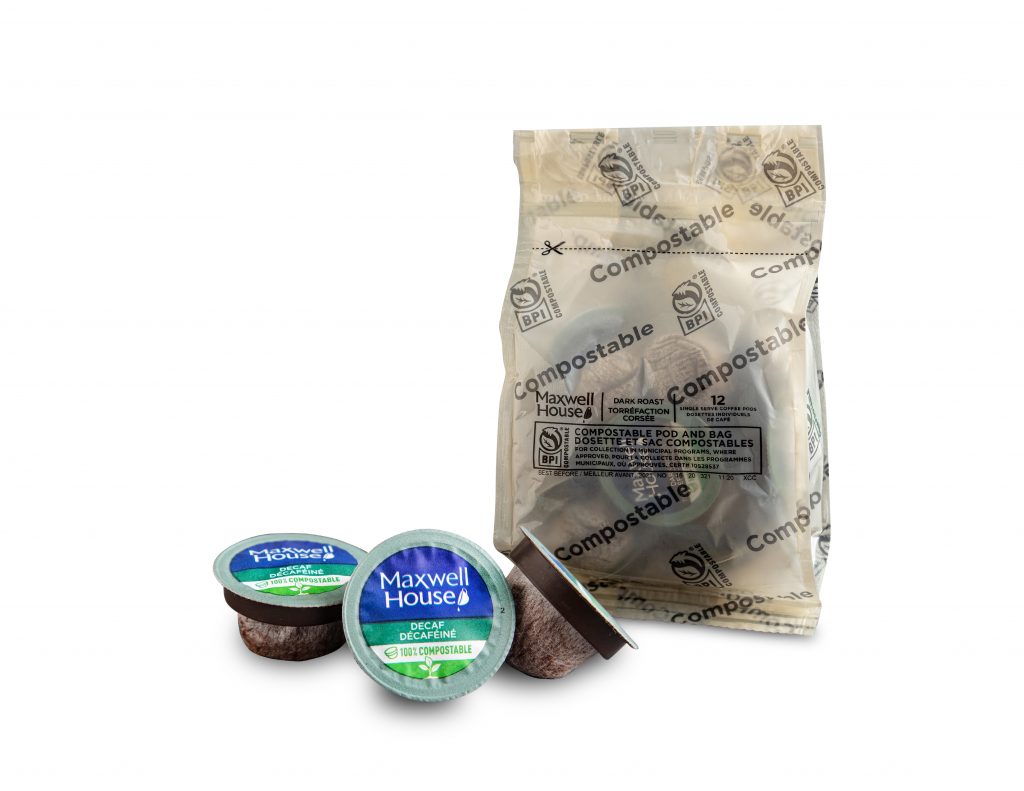

Since 1999, many companies have chosen to put their compostable products through rigorous testing, including the ASTM D6400, through the Biodegradable Products Institute (BPI). If a product passes the testing, the company can then pay to use the “certified compostable” logo on products, and the products also will be featured in BPI’s catalog.

Today, BPI has more than 10,000 approved, certified compostable products in its catalog. However, the majority of food packages and beverage containers still aren’t touting the certified compostable logo because, in addition to the costly certification, packaging products also have to have the necessary performance requirements—and go through other sets of testing—to ensure they will survive the long journey from the packaging production line to the end of life. And that’s no small order when you’re packaging consumables.

Many common packages and containers consist of multiple layers so that the product will last and perform as it is meant to for the duration of its life, while simultaneously protecting the contents inside. Hot cups, for example, are primarily made from paperboard, many grades of which are inherently compostable. To keep the cup from falling apart in consumers’ hands once filled with a hot beverage, the paperboard is often extrusion coated with a layer of polyethylene resin. The poly-coating also helps seal the cup at the seam. But because modern cup-making machines move at very high speeds—up to 400 cups per minute—to keep up with the growing demand, an adhesion layer is also needed to enhance the sealing properties. Chemical primers and coatings typically act as adhesion promoters in these applications, and they can also minimize cup defects called “flaggers” that cause leaking and other failures in the cup, as well as improve the surface of the cup so that inks can adhere better. However, most standard polyethylene resins and adhesion promoters are not considered compostable. As a result, more than 105 million paper hot cups are being disposed of (mostly in landfills) every day in the U.S. alone, according to The Freedonia Group’s “U.S. Cups and Lids” study.

For a package to be truly compostable, there must be a compostable product offering or technology at every step in the supply chain. In recent years, there have been a lot of advances in bio-based resin technologies. There are now a variety of compostable bio-based resins, like PLA and PHA, that can be used as suitable replacements to traditional resins in a variety of applications, including hot cups. However, compostable adhesion promoters for multi-layer packages and containers were still hard to come by until recently. Companies like Mica Corporation are starting to develop and manufacture adhesion promoters that completely degrade in commercial composting facilities and provide the necessary performance and regulatory requirements to create fully functioning packages and structures. With the introduction of these new compostable products to the packaging market—along with established test methods, clear definitions and guidelines, and increasing consumer interest—a future where viable compostable packaging is commonplace may not be too far away.

Jessi Spadaccino is the communications manager at Mica Corporation. Reach her at

jspadaccino@mica-corp.com.