FlexPack VOICE® profiles colleges, universities, and schools that have developed programs to train people for work in the packaging industry. In this issue, we talk to Jeff Thorstad, a faculty member at Hennepin Technical College based in Minnesota.

FlexPack VOICE®: Tell us a little bit about your programs.

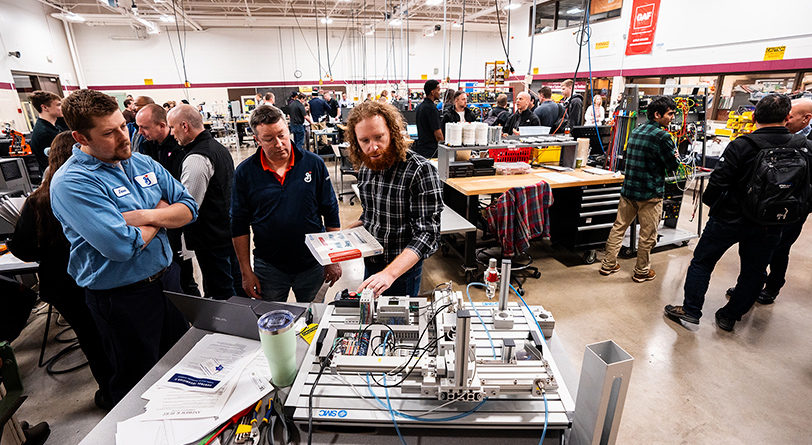

Jeff Thorstad: Our program was founded in 1973 with the strong backing of PMMI, the Association for Packaging and Processing Technologies, and other industrial groups focused on the packaging industry. Originally, the program name was Packaging Machinery Systems. Over time, as automation and robotics became common, our name was changed to Automation Robotics Engineering Technology. We maintain a strong focus on the packaging industry, while the skills we teach apply throughout all areas of manufacturing. We currently offer three degrees: automation robotics engineering, mechatronics, and automated machinery repair. The majority of our machines have been donated by packaging companies such as Delkor Systems and MGS Machinery. We aligned our curriculum with the PMMI Mechatronics certifications and work to ensure our students are well-versed in packaging machinery applications. The training we provide is focused on students ultimately becoming field service technicians or maintenance mechanics.

FPV: What are the key skills employers are looking for?

JT: We have found that our employers are looking for true multiskilled technicians. This means that the tech can fix most of the problems encountered on the floor, whether they are mechanical, electrical, or related to pneumatics. Companies can no longer have technicians focused only on one area and need the techs to be jacks-of-all-trades. This includes the ability to work with programmable logic controllers and robotic systems to make sure the systems are fully operational. Our students should be able to fix most problems they encounter and, if they are unable to fix them themselves, know who to contact for further information and assistance. This need led us to develop our mechatronics degree. In addition to the technical skills needed as a technician, communication skills are vital. Technicians must be able to communicate with others to be able to explain systems and what was done to correct an issue. Based on the wide range of companies that hire our students, we think we have been successful in creating an educational experience that promotes students to be multiskilled technicians.

FPV: What do you see as future challenges in manufacturing?

JT: As most companies realize, skilled labor will be the biggest future challenge for the manufacturing industry. Attracting and retaining qualified workers should be a priority, as well as automating any process that can be automated. Companies can also consider collaborating with potential employees to develop the needed workforce as new employees with degrees and experience are very hard to find now and will continue to be difficult to attract. An excellent opportunity for companies is to develop apprenticeships or maintenance-training programs to build their workforce. With this, it can benefit both the company and the employee by combining on-the-job training with a strong education. Moving forward, educators and industry leaders must develop strong partnerships to develop a future workforce. Both groups may need to adjust to the current labor needs and adopt greater flexibility to allow employees to develop skills for the future. We have worked with the industry to develop a classroom schedule that allows for flexibility and for part-time students so that our students can gain an education while working full time.

FPV: What emphasis do you put on flexible packaging, if any?

JT: We have a couple of small baggers that our students can work with, as well as a wrapper that provides real-world experience for our students. We also go on many industry tours to see equipment operating and to see applications that we are unable to demonstrate in our labs. Additionally, partnerships with PMMI and IoPPMN (Institute of Packaging Professionals) allow us to attend PACK EXPO and local trade shows to see the latest innovations in packaging technology.

FPV: Anything to add?

JT: We recently had a reverse career fair in our program where our students had booths, and the employers walked around to the students. This was the fifth or sixth year we have done this, and the feedback from the industry has been extremely positive. We had over 50 companies attend, and most of our students were offered formal interviews.