Learning About Labeling

Labelexpo Americas 2024 Showcases Industry Trends and Innovations

Later this month, packaging industry professionals from around the world will gather in Rosemont, Illinois, for Labelexpo Americas 2024 to learn more about the challenges and innovations in the industry. The show will include live demonstrations of flexo presses and will display digital technology and finishing equipment, but it also will focus on trends facing the industry.

“Sustainability will be a key focus of Labelexpo Americas,” says Tasha Ventimiglia, group director for Labelexpo Americas.

For example, to demonstrate sustainability efforts, the show’s organizers will be working with Convergen Energy, TLMI (Tag and Label Manufacturers Institute), and Rosemont Exposition Services on a live program that allows exhibitors to dispose of their waste in a more sustainable manner. The goal is to divert materials that exhibitors use during the show that would otherwise go into landfills.

The waste will then be converted into fuel pellets for commercial sale, Ventimiglia says. Wisconsin-based Convergen Energy develops businesses that produce renewable energy, alternative fuel products, and sustainable solutions for nonrecyclable materials, including producing a fuel pellet from industrial by-products.

“Our goal is to work with the label industry to provide cost-effective means to send nonrecyclable by-products to our facility,” Convergen CEO Ted Hansen said in an interview with the event organizers posted on the website for Labelexpo Americas. “We try to use a come-as-you-are approach and accept materials in loose, bale, roll, and almost any other form the customer has.”

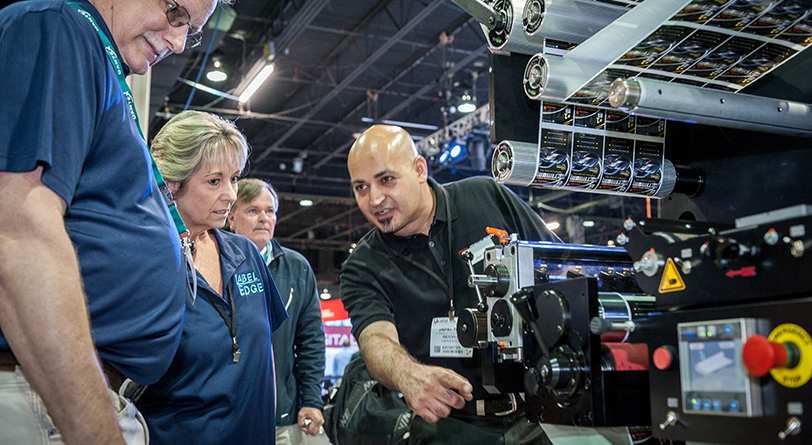

Various label and direct-package printing technologies were on display at Labelexpo Americas 2022 in Rosemont, Illinois.

By participating in the collection program at the show, exhibitors can see firsthand how easy it is to get materials to Convergen, he added.

“One way the show helps is by providing the exhibitors with a real-life example of how landfill avoidance can be achieved with their materials.”

At several sites at the convention center, exhibitors can drop off pressure-sensitive label stock, flexible packaging, shrink wrap, and metalized polyethylene terephthalate. Convergen has been operating the collection program at Labelexpo Americas since 2016.

Challenges and Opportunities

Sustainability is one trend facing the label and package printing industry. Automation, diversification from labels into flexible packaging, and digitalization are key topics trending in the industry, Ventimiglia says. Workforce issues remain one of the key challenges facing the industry as well, including recruiting skilled shop-floor machine operators. Other challenges include continued increases in the cost of label materials, inks, and coatings, and helping brands anticipate future sustainability mandates.

“Sustainable technology is constantly evolving as brands, states, and governments continue to issue mandates and regulations for packaging,” she says. “… At the same time, the push toward circular material economies will drive developments in removable adhesives and material identification and recovery systems.”

The various issues make it challenging for companies operating today, says Andy Thomas-Emans, strategic director for Informa Labels and Packaging Group, which is also involved with running the show held September 10–12, 2024.

“Long-term profitability is perhaps the greatest challenge facing label converters in the face of rising labor and business costs, legislative uncertainty, and consolidation of each end of the supply chain—manufacturers and brand owners—squeezing converters in the middle,” Thomas-Emans says.

But there are still major opportunities for growth in the labels and package printing industries, Thomas- Emans and Ventimiglia say.

“We have seen in the U.S. a major proliferation of dynamic ‘challenger’ brands across the whole consumer landscape—from clothing to cosmetics and craft beers and gins to gifting,” Ventimiglia says. “These companies are highly marketing-focused and are open to label converters offering innovative consumer engagement solutions involving cutting-edge print and decoration techniques.”

“Developments in technology are opening up huge opportunities for label converters to differentiate themselves in a highly commoditized market, and so restore margins of profitability.”

—Andy Thomas-Emans, strategic director for Informa Labels and Packaging Group

Global brands have been putting packaging innovation at the forefront of their marketing strategies, creating opportunities for label converters to add value, she adds.

Technological advances also are providing opportunities, Thomas-Emans says.

“Developments in technology are opening up tremendous opportunities for label converters to differentiate themselves in a highly commoditized market, and so restore margins of profitability,” he says. “Just some things to look out for at this year’s Labelexpo Americas include energy and waste-saving technologies such as LED-UV and factory automation, along with digital embellishment, diversification into stand-up pouch printing and manufacture, and sustainable materials and adhesives technologies.”

The expo will have a strong focus on how converters can get involved in the radio-frequency identification (RFID) revolution, Ventimiglia says. That will include an event on Thursday, September 12, 2024, when the Label Academy will present a half-day workshop on RFID in labels and package printing.

Topics delivered by industry experts include understanding the Walmart RFID mandate; a comprehensive overview of RFID technology; the equipment required to convert, test, and encode RFID labels and tags; and case studies of RFID in action.

Thomas-Emans says that digitization and automation are closely related and will be key themes at the expo.

“There is a huge shift toward reducing manual input to the entire factory process from invoicing and inventory management through to shop-floor machinery,” he says. “This is a function both of an acute shortage of skilled labor and the need to reduce operating costs and improve overall efficiency.”

Flexo presses are advanced machine tools with all parameters—from pressure-setting and registration to tension control—set automatically and stored for future recall.

“Now, we are seeing automation extending to finishing and converting systems and integrating inkjet varnishing and digital metallization into print and converting machine lines,” Thomas-Emans adds.

Looking Toward AI

The evolution of artificial intelligence (AI) also is being monitored.

“AI will become increasingly important to the label and package printing industry as we move toward a more automated future, minimizing the amount of manual input into all aspects of the label and package printing converting business—from lead generation to production planning and quality control,” Ventimiglia says. “True AI has a ‘creative’ aspect, actively suggesting new courses of action—for example, the way a job might move through a print factory depends on available resources and priorities, or with inspection systems trained to identify errors before they result in waste material and suggesting remedial measures. So, AI has a massive potential to augment—not replace—human skill.”

Thomas-Emans says he recognizes the potential for AI, but the industry should be cautious.

“The first real-world applications of AI are likely to be in label design, then in print and converting inspection and in complex job planning through the converting plant,” he says. “We should, however, be wary of overhyping AI and mistaking it for machine learning, which has been with us for some time.”

More at the Show

Overall, attendees will get an immersion into the latest thinking going on in the industry, Ventimiglia says.

“The FlexPack @ Labelexpo show feature will allow attendees to see short-run, added-value flexible packaging, including all the ancillary equipment, thermal lamination, pouching equipment, materials, and coatings required to enter this demanding market,” she says.

Thomas-Emans points out that the show highlights the importance of flexography printing.

“For me, one of the most interesting trends will be the re-emergence of flexography as a key driver of innovation. At the last Labelexpo Americas show, there was not a single flexo press, leading to speculation about the ‘death of flexo,’” he says. “At this year’s show, we will see the launch of multiple 26-inch ‘mid-web’ flexo presses featuring high degrees of automation and the ability to shift rapidly between different label and packaging materials—shrink sleeves to in-mold labels to flexible packaging and wrap-around film. This allows the label converters to diversify into markets adjacent to self-adhesive labels.”

Sponsors of the show include media partners and various packaging associations, including the Flexible Packaging Association and TLMI.

“TLMI values the partnership with the Labelexpo organization and what it means to our industry to bring together so many leaders,” said Linnea Keen, TLMI president, in a statement. “In addition to exhibiting, TLMI will be hosting Eco Stage with the most recent trends and updates related to sustainability.”

Editor’s note: All photos are courtesy of Labelexpo Americas 2024.

Thomas A. Barstow is senior editor of FlexPack VOICE®.

Sidebar: About Labelexpo Americas 2024

What: The trade show will include more than 400 exhibitors. Various networking events, including talks and “academies” such as the Label Academy Flexible Packaging Master Class, will be held throughout the show.

When: Tuesday, September 10 to Thursday, September 12

Where: Donald E. Stephens Convention Center in Rosemont, Illinois

More information: Go to labelexpo-americas.com to also register.